3D printing technology, also known as additive manufacturing, is revolutionizing jewelry design by allowing for the creation of intricate and personalized pieces directly from digital models. In this process, designers use CAD (computer-aided design) software to develop detailed 3D models of jewelry, which are then printed layer by layer using specialized materials such as wax, resin, or metal. This precise technology not only enables the production of complex and unique designs that would be difficult or impossible to create by hand, but it also streamlines the entire jewelry production process, from prototyping to final product.

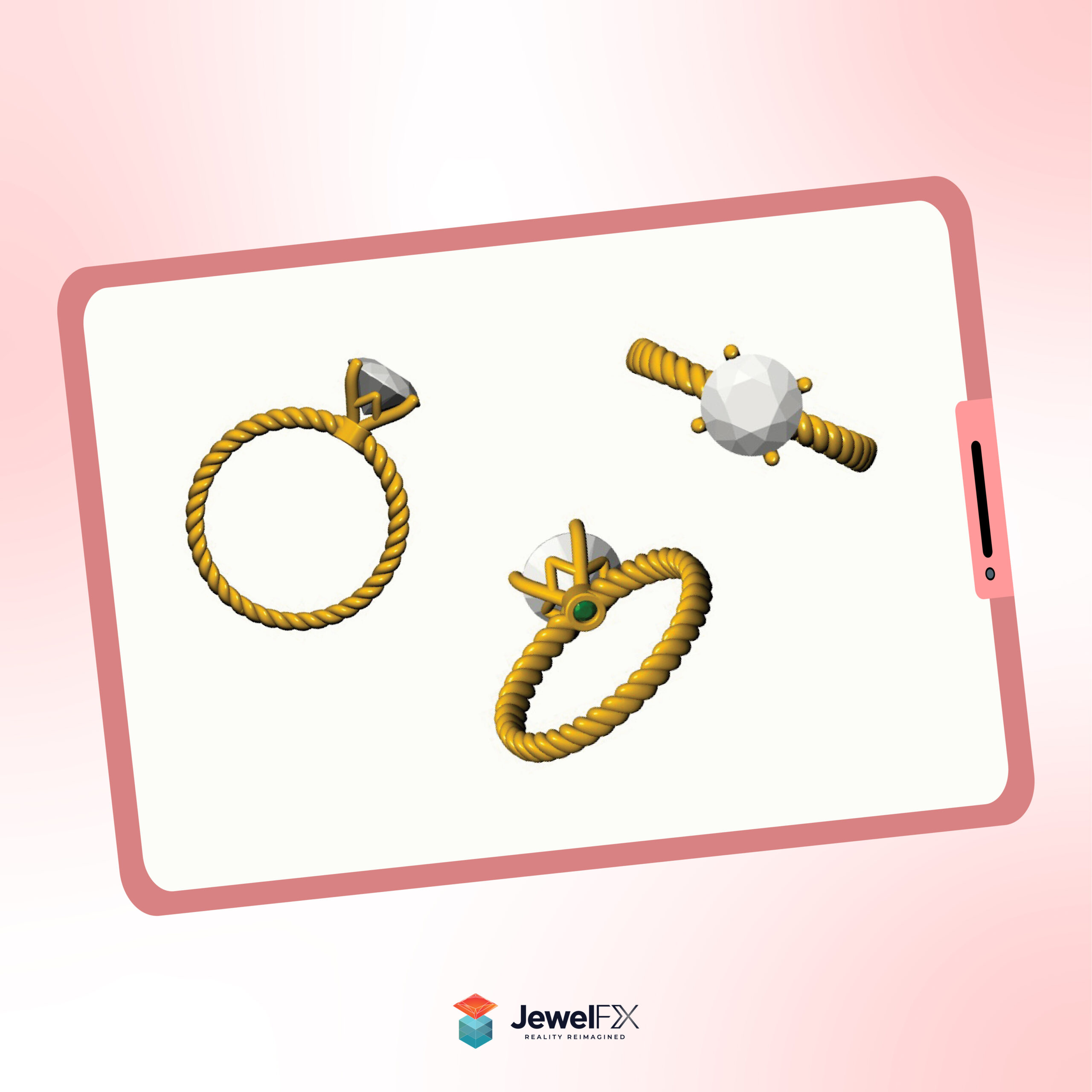

The jewelry creation process begins with detailed design work, where Computer-Aided Design (CAD) software is used to craft precise 3D models. Designers use CAD to experiment with different styles, dimensions, and intricate details, allowing them to visualize the final product before it is ever made. This technology provides the flexibility to refine and customize designs, ensuring accuracy in both form and functionality. CAD modeling is essential in modern jewelry making, as it bridges the gap between creativity and engineering, bringing artistic visions to life.

Once the 3D model is finalized, the design is fed into a 3D printer, which transforms the digital model into a physical prototype. Using materials such as resin or wax, the printer meticulously layers the material to form the jewelry piece. This step allows jewelers to create prototypes that closely resemble the final product, giving them the chance to check for any design flaws or adjustments before moving to production. 3D printing is not only fast and efficient but also ensures the utmost precision in every detail.

After the prototype is printed, it undergoes a finishing process to achieve the desired appearance and texture. Post-processing techniques like polishing help smooth out any rough surfaces, while casting involves creating a mold for mass production. Electroplating is often used to add a thin layer of metal, such as gold or silver, to give the jewelry its final shine and durability. These finishing touches are crucial to achieving a polished, high-quality piece of jewelry that is ready for market or customer presentation.

3D printing has revolutionized jewelry design, offering intricate detailing, customization, and rapid prototyping. Among the common materials used are precious metals like gold, silver, and platinum, which provide luxury and durability. These metals are often used for high-end, fine jewelry and can be 3D printed via methods such as Direct Metal Laser Sintering (DMLS). On the other hand, non-metallic materials like resin and nylon are often utilized for prototyping or creating experimental, fashion-forward pieces. Resin, known for its precision, is ideal for creating intricate molds, while nylon is lightweight and flexible, offering versatility for modern, bold designs.

Here is a table comparing various material properties and their suitability for jewelry making:

| Material | Hardness (Mohs Scale) | Density (g/cm³) | Tarnish Resistance | Durability | Hypoallergenic | Aesthetic Appeal | Suitability for Jewelry |

| Gold | 2.5 – 3 | 19.3 | High | High | Yes | High (Lustrous, Warm) | Excellent |

| Silver | 2.5 – 3 | 10.5 | Moderate | Medium | Yes | High (Bright, Reflective) | Very Good |

| Platinum | 4 – 4.5 | 21.45 | Very High | Very High | Yes | High (Bright White) | Excellent |

| Titanium | 6 | 4.5 | Very High | Very High | Yes | Medium (Matte Finish) | Very Good |

| Stainless Steel | 5.5 – 6.3 | 7.8 | High | High | Yes | Medium (Modern, Sleek) | Good |

| Copper | 2.5 – 3 | 8.96 | Low | Low | No | Medium (Reddish-Brown) | Fair |

| Brass | 3 – 4 | 8.4 | Low | Medium | No | Medium (Yellowish) | Fair |

| Palladium | 4.75 | 12.02 | Very High | High | Yes | High (Silvery White) | Excellent |

| Tungsten | 7.5 – 9 | 19.25 | Very High | Very High | Yes | Low (Dark Gray) | Good |

| Zinc | 2.5 | 7.14 | Low | Low | No | Low | Poor |

This comparison highlights the various characteristics that make certain materials more or less suitable for jewelry, depending on factors like durability, hypoallergenic properties, and aesthetic appeal.

The adoption of new manufacturing techniques, particularly in fields like 3D printing, CNC machining, or additive manufacturing, often faces significant challenges. One of the primary hurdles is the high cost of the initial setup. The procurement of advanced machinery, equipment, and software, alongside the need for skilled personnel, results in steep upfront investments, which may deter businesses, especially smaller enterprises. Additionally, material limitations pose another barrier; certain technologies may only support specific materials, restricting flexibility in design or limiting product durability. Post-processing requirements further add complexity to the workflow, as many parts may require finishing touches, such as sanding, polishing, or coating, to meet industry standards, increasing both labor and time costs. These factors combined create a challenging environment for industries looking to innovate with modern production techniques.

Advancements in technology are gradually reducing the barriers associated with high setup costs, material limitations, and post-processing requirements. For instance, as 3D printing technology continues to evolve, more affordable machines with better precision are becoming accessible to small and medium enterprises. Open-source software and cloud-based platforms also reduce the need for costly proprietary solutions. In terms of material limitations, researchers are developing new composites and bio-materials that expand the range of materials that can be used, offering enhanced flexibility. Post-processing automation, such as robotic finishing or laser polishing, is increasingly integrated into workflows to streamline production. Furthermore, artificial intelligence and machine learning are now being employed to optimize manufacturing processes, reducing waste and energy consumption, ultimately helping companies lower operational costs and improve output quality.

3D printing is dramatically transforming the jewelry industry by blending technology with artistry. It empowers designers with new creative freedoms, accelerates production processes, and caters to consumer desires for personalization and ethical practices. The industry is shifting from being exclusively handcrafted to a hybrid of traditional craftsmanship and digital innovation.

In the future, 3D printing will likely continue to evolve with even more advanced materials, better printing speeds, and finer precision. It will further democratize jewelry design, allowing hobbyists, small businesses, and large brands alike to push the boundaries of what’s possible in jewelry creation. This shift ensures that 3D printing will remain a pivotal technology in shaping the future of jewelry design and manufacturing.